Human-powered prints to elevate your next project, product, business venture, or special occasion, including:

Wedding Suites

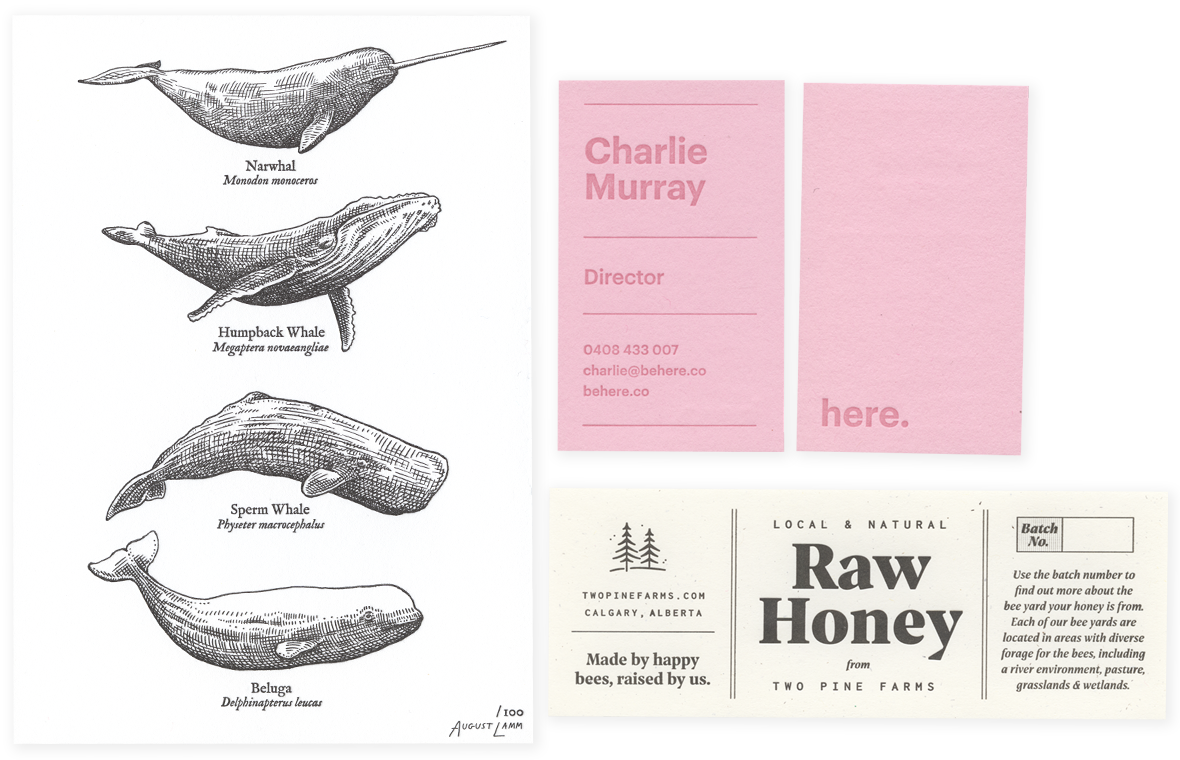

Business Cards

Labels + Hang-Tags

Packaging

Unique Gifts

Personalized Stationery

Greeting Cards

Posters

Art Prints

Book Jackets

Request a printing quote.

Check our file prep guidelines.

WANT TO WORK TOGETHER?

SOME THINGS TO NOTE:

MINIMUMS

We don’t have strict minimums for projects, but it’s definitely more cost-effective to print in larger quantities! We recommend at least 100 business cards, or 50 pieces for other projects.

MAX. SIZE

The largest paper size we can print on is 16x22”. The largest printed area we can accommodate with polymer plates is 13x19”. Small sizes are no problem.

PROJECT PROOFS

Due to the nature of letterpress, we only offer digital project proofs. We’ll take our time walking you through samples to give you a clear idea of what to expect, but at the end of the day we ask our clients to take a leap of faith and trust the process. By the time we get a project on the press, most of the labour and cost-of-materials have already been invested, so we do require commitment ahead of time. Very special exceptions can be made for clients with accommodating budgets and timelines.

NO FOIL HERE, BABY

Though beautiful, our studio just isn’t set up to offer hot foil services.

BUDGET CONSIDERATIONS

The factors that most significantly impact your project costs are print size, quantity, number of colours, and paper stock. We can work with you to adjust any of these variables to hit a sweet spot in your budget. For example – each colour in a design requires its own plate to be made, a unique ink to be mixed, and a separate run through the press (which really adds up, if you’re talking 500 business cards). Simplifying your design can result in significant savings.

FINISHING

Ask us about edge painting, and any other special touches your project might need – like scoring, folding, diecutting, or digitally printed components!

BUSINESS CARD PRICING

3.5 X 2” | STOCK: CRANE LETTRA #220

Our “per colour” pricing is based on how many times a card is hand fed into the press. If you have black on the front of your card and on the back, that counts as two colours. (Because they have to be printed separately!) *Prices do not include GST.

A HELPFUL GLOSSARY

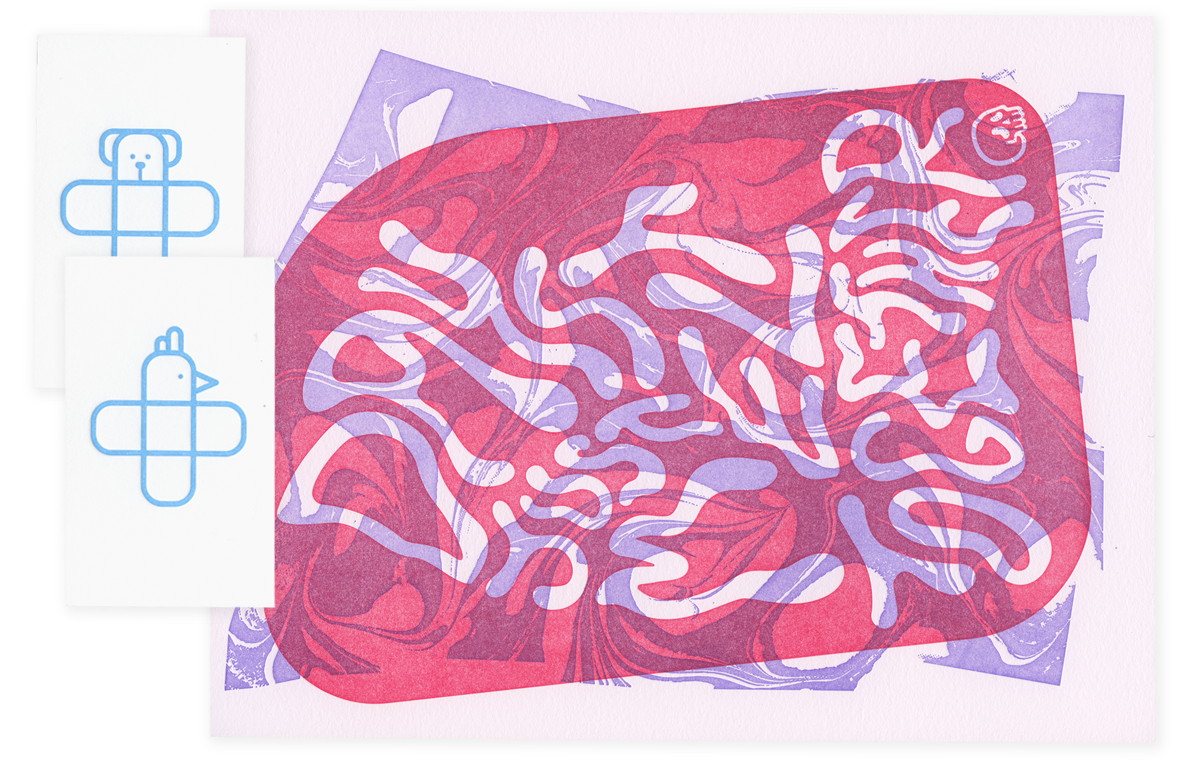

SPLIT FOUNTAIN

Achieved by putting 2 (or more) ink colours on the rollers and allowing them to blend as the press runs, this beautiful technique creates a gradient effect, and unique variation throughout a print run.

OVERPRINTING

Use the transparency of letterpress inks to your advantage! Since they pick up and darken the tone of whatever’s beneath them (paper or ink) you can use two colours to create three! (Think yellow + blue = green.)

UNCOATED PANTONES

We hand mix every colour in the studio, measuring ink to the hundredth of a gram. For each colour in your design you’ll need to choose a Pantone from the Solid Uncoated swatch book, including metallic and fluorescent inks.

SOLID COLOUR WASHES

We love the ‘salty’ effect of a solid flood on the press. Because letterpress inks are semi-transparent, the texture of the paper shows through and creates a distinct grain or patchiness. It’s a unique vibe, and definitely different from digital printing. Don’t expect the solid blocks of colour in your designs to translate as smoothly as they do on screen.

VARIANCE

Our presses are between 60 and 100 years old, and every aspect of production in the studio is done by hand. While we obsess over details, the reality (and beauty) of letterpress is that no two prints are exactly the same. Texture and subtle variations are inherent in this medium. It’s what made us fall in love in the first place.

BLIND DEBOSS

A favourite technique in the studio, especially when using double thick Crane Lettra, a blind deboss is printing with no ink – just impression. On your quote you will see this reflected as a “colour” since each piece will be hand fed through the press just the same.